Gradinlift Underwater Scissor Lift Platform for Pearl River Hydraulic Research Institute

Client Overview:

Client: Pearl River Water Resources Commission, Pearl River Hydraulic Research Institute

Application: The Gradinlift underwater scissor lift platform is used to install rock models and experimental equipment, simulating various water depth conditions for the research institute’s experimental needs.

Customer Requirements:

1. Structure & Material:

Hydraulic transmission with a dual-span, single-layer design.

316L stainless steel construction with an adjustable diameter of 10 meters.

Lifting stroke of ≥5.3 meters and rated load capacity ≥11 tons.

2. Control & Monitoring:

On-site and remote control capabilities.

Control cabinet with dehumidification and anti-salt protection.

At least two underwater pull-wire sensors for height monitoring with positioning accuracy ≤±5mm.

3.Safety

Emergency stop, overload protection, explosion-proof systems, manual descent, and phase-loss protection.

Anti-fall mechanism with at least four hydraulic telescopic supports.

4. Performance

Lifting speed ≥0.4 m/min.

Hydraulic system with check valves.

Double-sealed hydraulic cylinders.

Uniform load distribution of ≥1t/m² and overall flatness error of ±5mm.

5. Design Details

Platform panel thickness ≥6mm, integrated mooring rings, and inspection hatches.

Waterproof edges with adhesive sealing strips and detachable railings (21 posts with 1.5m spacing).

Solution Provided by Gradinlift:

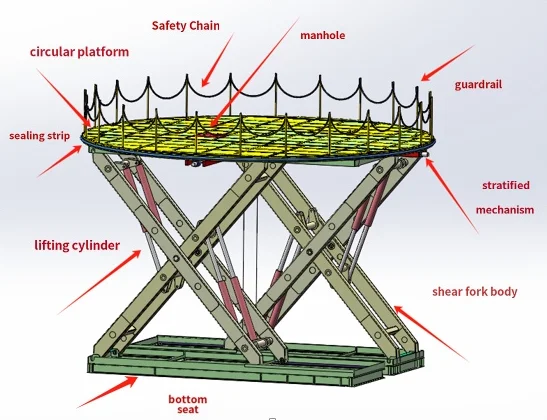

Gradinlift’s 316L stainless steel underwater scissor lift platform was designed to meet the exacting requirements of the Pearl River Hydraulic Research Institute, ensuring precision, safety, and durability for underwater applications.

1.Structure & Material

The platform is built with a dual-span, single-layer hydraulic transmission system, made from 316L stainless steel for excellent corrosion resistance. The adjustable diameter (10m) and lifting stroke of ≥5.3 meters with a load capacity of ≥11 tons make it ideal for the client’s experimental needs.

2.Control & Monitoring

The platform offers both on-site and remote control, making it versatile for different operating conditions. The control cabinet features a dehumidification and anti-salt protection system to prevent damage in underwater environments. Underwater sensors monitor the lifting height, with positioning accuracy of ≤±5mm, ensuring precise operations during experiments.

3.Safety

The platform includes emergency stop, overload protection, and explosion-proof systems for secure operation. The anti-fall mechanism features hydraulic telescopic supports, providing stability and safety during prolonged use.

4.Performance

The system provides a lifting speed of ≥0.4 m/min, ensuring efficient operation. The hydraulic system incorporates check valves and double-sealed hydraulic cylinders for smooth, leak-free performance. The platform surface is capable of bearing ≥1t/m², with flatness error kept to ±5mm for high-precision experiments.

5.Design Details

The 6mm thick platform panels are fitted with mooring rings and inspection hatches. The waterproof design includes sealing strips along the edges and detachable railings for added safety, providing a secure environment for operations.

This custom-designed solution from Gradinlift successfully addressed the Pearl River Hydraulic Research Institute’s need for a reliable, high-performance underwater lifting platform. With its advanced safety features, precision, and durability, this platform is an ideal solution for demanding research applications.

Contact Gradinlift today to learn more about our custom solutions for your underwater and industrial lifting needs!