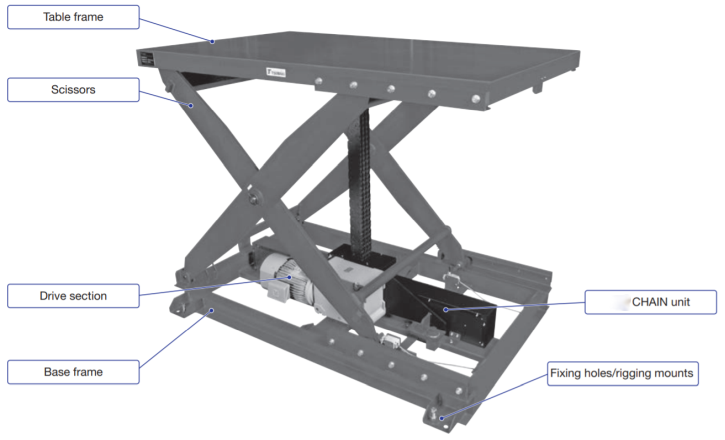

Double Rigid Chain Scissor Lift Tables

Double rigid chain scissor lift tables are industrial lifting equipment designed to raise and lower loads vertically. They feature two parallel rigid chain transmission systems, providing enhanced stability, higher weight capacity, and improved load distribution compared to single-chain systems. These lift tables offer precise positioning, versatility, and safety features, making them suitable for various industrial applications such as material handling, assembly lines, and warehousing.

Model | Double Rigid Chain Scissor Lift Tables |

Loading Capacity | Customized |

Platform Size | Customized |

Lifting Speed | 500 mm/sec (Customized) |

Power Supply | 380V/50HZ |

Application | material handling, assembly lines, warehouses, and logistics facilities |

- Dual Rigid Chain Transmission: Utilizes two parallel rigid chain transmission systems for lifting and lowering loads vertically, ensuring balanced and stable operation.

Fewer Components: The rigid chain transmission system simplifies the design by reducing the number of components required for operation. This not only streamlines the manufacturing process but also minimizes the chances of component failure, leading to improved reliability.

High Cycle Volume: This system is capable of handling a high volume of lifting cycles with minimal wear and tear. It is well-suited for applications that require frequent lifting and lowering of loads, ensuring consistent performance over time.

Low Maintenance: Compared to traditional systems, the rigid chain transmission system requires less maintenance. With fewer moving parts and no hydraulic fluid or lubrication needed, maintenance tasks are minimized, reducing downtime and associated costs.

Large Product Life: The robust design of the rigid chain transmission system contributes to its long product life. It can withstand heavy loads and frequent use without compromising performance or reliability, providing a durable solution for lifting applications.

Stable and Precise Positioning: The rigid chain transmission system offers stable and precise positioning of the lifting platform. This is essential for applications that require accurate placement of loads, ensuring efficiency and safety in operations.

No Lubrication Needed: Unlike hydraulic systems or belt-driven mechanisms that require regular lubrication, the rigid chain transmission system operates without the need for lubrication. This eliminates the risk of oil leaks or contamination and reduces maintenance requirements.