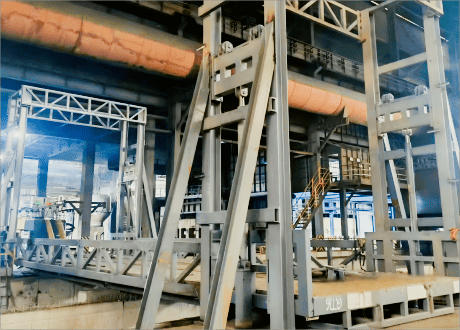

Heavy Duty Ladle Scissor Lifts for Steel Industry

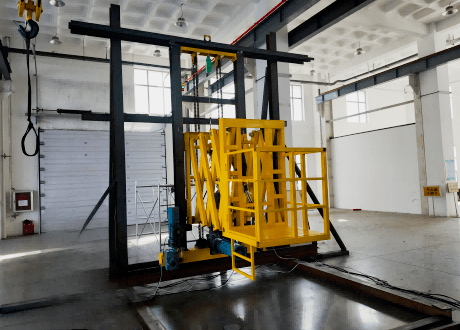

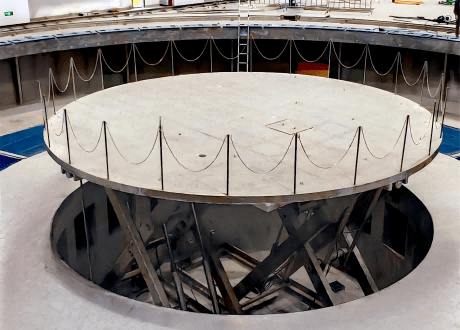

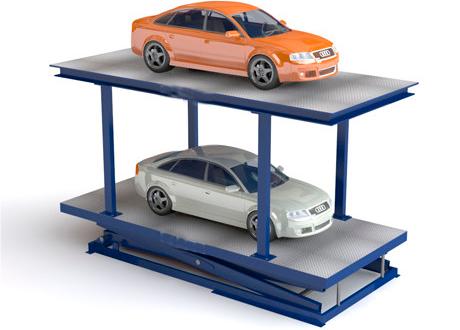

Introducing our Heavy Duty Ladle Scissor Lift, designed to meet the unique demands of steel companies operating blast furnaces. It replaces traditional scaffolding for brick replacement in ladles used for pouring molten metal. Mounted using a crane, it can easily move between ladles. With a two-stage scissor lift mechanism, it’s built to withstand harsh smelting environments. Our lift ensures worker safety and ergonomic efficiency during bricklaying tasks. Customized for each ladle’s shape, it reduces downtime, minimizes injuries, and enhances overall productivity. Operated via handheld controller, it handles loads up to 5 tons with ease, thanks to its aluminum extension pieces for larger ladles.

Model | Heavy Duty Ladle Scissor Lift for Steel Industry | Range |

Loading Capacity | 5000kg | as required |

Platform Diameter | 3000mm | as required |

Travel Height | 2500mm | as required |

Actuation | Hydraulic | Hydraulic/Mechanical |

Voltage/Phase | 460V/ 3 Phase | as required |

Application | Iron & Steel Industries | |

Heavy-duty high-rise table with custom profile top: Our lift is equipped with a sturdy high-rise table featuring a customizable top surface, providing a stable platform for ladle handling tasks tailored to specific requirements.

Enhanced Safety: Engineered with safety at the forefront, our scissor lift ensures a secure working environment, minimizing the risk of accidents during ladle handling tasks.

Improved Efficiency: Designed to enhance efficiency, our lift streamlines ladle maintenance operations, reducing downtime and optimizing productivity in demanding industrial environments.

Special Controls and Protection: Equipped with specialized controls and built-in protection mechanisms, our lift offers intuitive operation and robust defense against the rigors of harsh foundry environments.

Versatile Lifting Platform: The lifting platform of our scissor lift is available in flat configuration or with an optional perimeter kick plate, providing flexibility to accommodate different ladle sizes and shapes while ensuring added safety during operation.