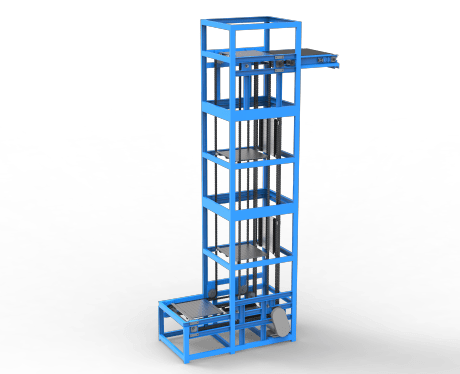

VRC| Continuous Vertical Conveyor Lifts

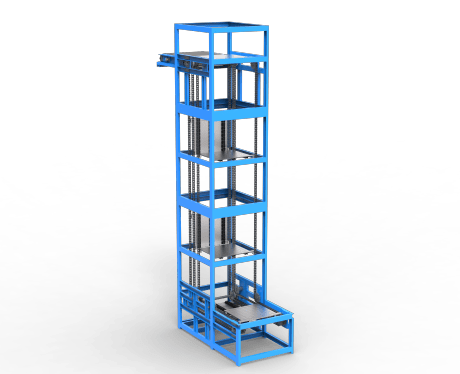

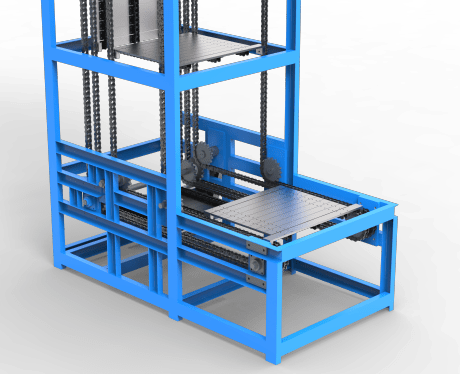

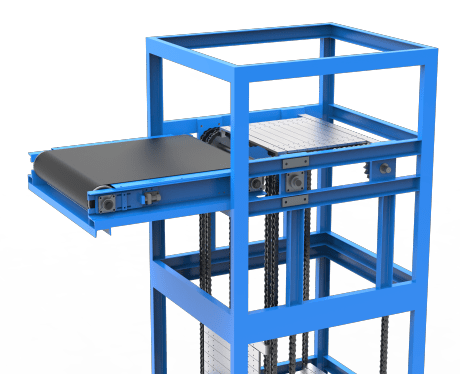

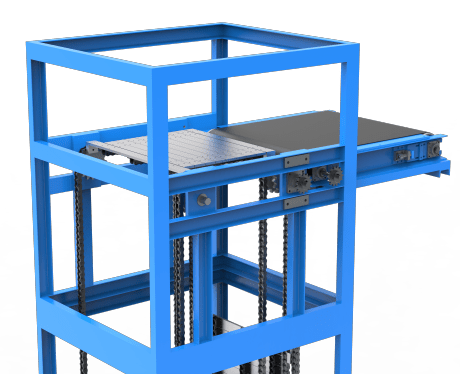

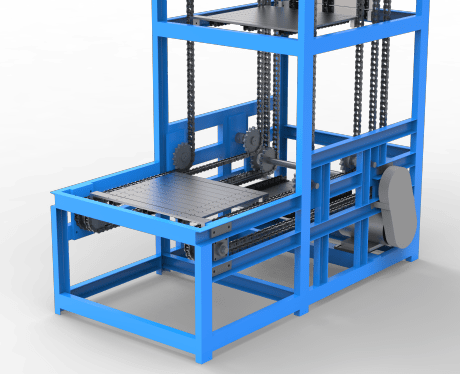

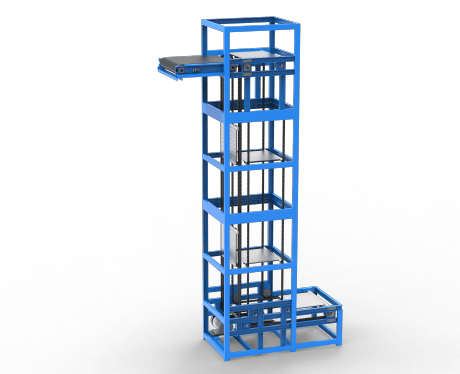

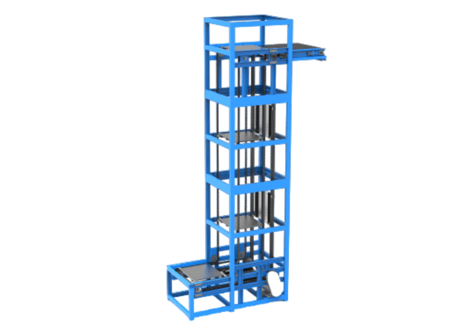

A continuous vertical lift is a specialized equipment designed for lifting and conveying square-shaped items such as paper boxes, plastic crates, and other products. The main working principle of this machine involves utilizing four closed-loop chains for transmission. Equidistantly spaced load-bearing plates are installed along the chains. The transmission chains drive the load-bearing plates to complete four repetitive cycles: loading, lifting, unloading, and returning. The loading entrance is equipped with an automatic control roller conveyor line to facilitate intermittent loading. The main machine adopts variable frequency speed control, enabling flexible adjustment of speed, thus ensuring smoother operation of the logistics assembly line.

Model | Continuous Vertical Conveyor Lifts |

Lifting Capacity | 30KG (Customized, up to 2000KG) |

Cargo Lift Speed | 8s/set (can be adjustable) |

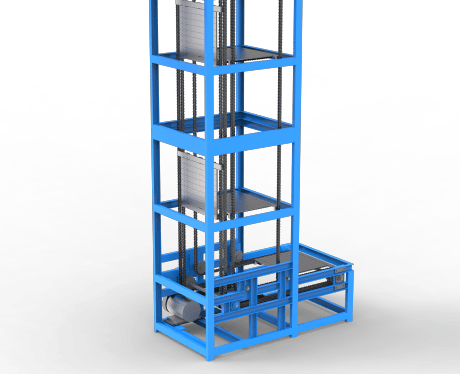

Lifting Height | 9320mm (Customized) |

Levels | 1 to 6 stops (Customized) |

Chain Plate Size | 900mm*1000mm (Customized) |

Application | Moving heavy boxes, cargo, and pallets from one level to another. |

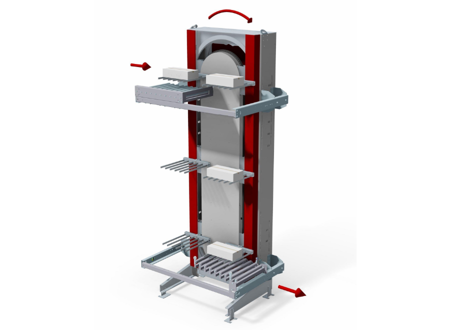

Directional Variation: They can be configured into Z-type or C-type based on the direction of entry and exit transportation.

Efficiency: During operation, the return of the pallets doesn’t occupy working beats, ensuring high efficiency regardless of the conveying height.

Material Limitation: They are capable of transporting only goods, with a minimum size limit for the materials.

Operation Mode: They typically operate in a unidirectional mode but can also run bidirectionally.

Carrying Capacity: These lifts have a large carrying capacity, often up to 2000kg, making them suitable for heavy loads.

Automation Compatibility: When paired with entry and exit transportation equipment, they enable fully automated conveying, eliminating the instability caused by manual operations.

Compact Design: Continuous vertical conveyor lifts feature a compact structure, requiring minimal floor space for installation.

Safety and Reliability: They are designed to be safe and reliable, with easy maintenance procedures, low operating costs, and effective cost reduction in the long term.